MACHINE PARK

How our always identical, perfectly round tortillas are made?

What is responsible for their manufacturing process is a range of technologically advanced, high precision and just as intelligent machines.

Thanks to them, you are getting a product of the highest quality – just as you like most.

Manufacturing execution system / MES

Tortilla is prepared with precision known in the pharmaceutical industry.

That is from where have borrowed accurate weighing system for recipe ingredients. We put a lot of effort to adapt it to our needs. Now we can be sure that in more than 200 kilo gram portion of the dough all the ingredients are weighed out really precisely. And you have to know that some of them must be added to an accuracy of a fraction of a gram. For your satisfaction

Mixer

This is no ordinary dough mixer. The mixing time and temperature must be calculated to the second. A dozen seconds more or less than needed, a few degrees difference in temperature – and the cake is good for nothing. Within a few short minutes of stirring, by a rapidly rotating specially shaped mixer, from the ingredients a dough with unique properties is produced. Only from such a dough a flexible, soft, fluffy tortilla can be formed – exactly what you like.

Divider-rounder

At this stage, the preparation tortilla does not like stress. The dough should be divided, and formed into a regular ball as gently as possible – with precision calculated in grams. This ingenious machine, which is like a Swiss watch, does not contain any electronics, but it splits and forms balls, mimicking the work of human hands. Although it does not look like a man, in his artificial hands it patiently creates hundreds of thousands of balls a day.

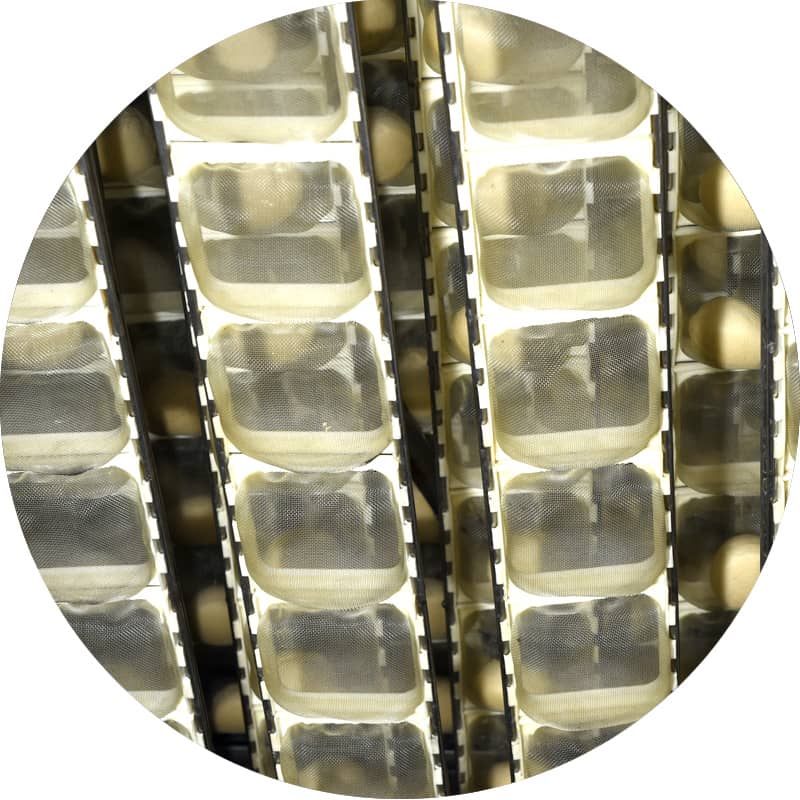

Proofer

Although we were very carefully, dough in balls must rest before making the transition into round tortillas. This is one of the largest machines. Inside, the few thousand balls wanders in individual baskets, at exactly the right time, temperature and humidity – similar to those that prevail in the summer at the beach. Then it gets even hotter!

Press

Try to drop a tennis ball on the table from a height of 2 meters, so that after landing it does not jump or roll to one side even by a centimetre. Easy? And this machine can do it! Dough balls are precisely placed side by side on the conveyor, which takes them to the press. After pressing the balls to the shape of tortilla, spacing between the pancakes will not exceed centimetre, so the balls are not allowed to move from side to side.

Pressing? Nothing big! One should keep an eye on 5 parameters related to: pressure, time and temperature of pressing. And then cause the tortillas to enter into the oven while keeping the same spacing between the rows. Otherwise they will burn! For this is a hard-working, intelligent transporter, which sets the spot in front of the oven in neat rows with the same intervals.

Oven

From the outside, it deserves to be called the most boring machine in the statement. Stationary metal block. But what happens inside! Imagine an Indian baking tortilla on the hot stone. Rotating it to both sides, for it to get evenly baked through contact with the hot stone. It took dozens of years to develop the furnace, which is doing exactly the same thing! Tortillas are baked as a result of contact with hot furnace plates – not from the hot air and radiation from hot parts of the furnace. Contact baking method combines with double rotation of tortilla, in order for both sides to be properly cooked. Without the participation of an Indian.

Baking is another 4 parameters associated with time and temperature. Set with an accuracy of one second and a degree.

Cooling and drying of tortillas

No one can enter this room. It is like a nuclear reactor chamber. Within three minutes, tortillas are cooling down from the temperature of almost one hundred degrees to less than 20 degrees Celsius. Also water partially evaporates, so at this point we ensure not only the cooling temperature, but also humidity, wherein the cooling process takes place.

Packing

After processing and fulfilment of the dozens of parameters, tortillas are ready for quality control and packaging.

In sterile conditions and cold we pack tortillas, trying to not touch them. Therefore, instead of human, tortillas are watched by an eye of the camera coupled to a computer, which has a memory image of the perfect tortilla. Within a minute, hundreds of tortillas are viewed, compared with the model and automatically transferred for packaging or rejected.

Another machine arranges the tortillas in equal piles, counting them on occasion. If it made a mistake in counting, electronic scale flow at the end of the packaging process will reject such a failure.

Packing machine gently wraps stacks of tortillas in foil and seals individual packages. It must be immune to minor differences in the size of tortillas or arrangement of stacks. Tortilla is after all a natural product, each one, although produced according to the same recipe is unique.

Then, inside the packages we let in a specially developed mixture of gases, which pushes oxygen in the air and allows us not overdo with preservatives inside the dough. What matters is, after all the taste and your satisfaction.

Have you ever wonder, how we create our snacks full of flavour and aroma?

The production of these specialities is a multistep and often highly complex process. For each stage of production corresponds different modern precise and very intelligent machine. Would you like to see them with your own eyes? We invite you on a virtual journey around the world DIJO FUN&FOOD.

Kneader

In this armoured machine with steel centimetre thick walls dough is knead. Just look at the electric motor driving the mixer! We, too, so far we have not seen anything so big!

Ekstruder

In order to obtain a unique shape and a unique crispiness, we are stamping our products at a high constant pressure controlled with a few percent tolerance. The dough is thick, so the construction of the extruder is specially prepared for original shapes.

Caustic bath

Here for the first time, we give our products the taste. Unique, the waterfall system of leaching covers carefully pretzels and sticks with hot solution of caustic soda. The more leached skin on the product, the more intense the flavour. Therefore, our thin pretzels are the most tasty product on the market – with an incomparable volume ratio of the product to its surface.

Oven

Furnace with caustic bath constitute a complex four-section system of baking. At the beginning the hot lye, then the living flame treatment, then baking, and then drying the product. The time in each section and the temperature are closely controlled in order to ensure that at the end of the furnace appears what you like.

Furnace looks like a lightweight contender, but it has the power of a heavyweight champion. It is more efficient and economical than older and heavier furnaces. All thanks to modern design and hot air circulation systems.

Seasoning

If you are requesting more flavour… Salty Snacks have their own unique flavour. It can be enriched through this device. Seasoning on the surface of the product and baking preserves the flavour for you. Seasoning do not escape into the heated furnace, and it does not alter the taste or intensity. Note, only the best are seasoning in this way!

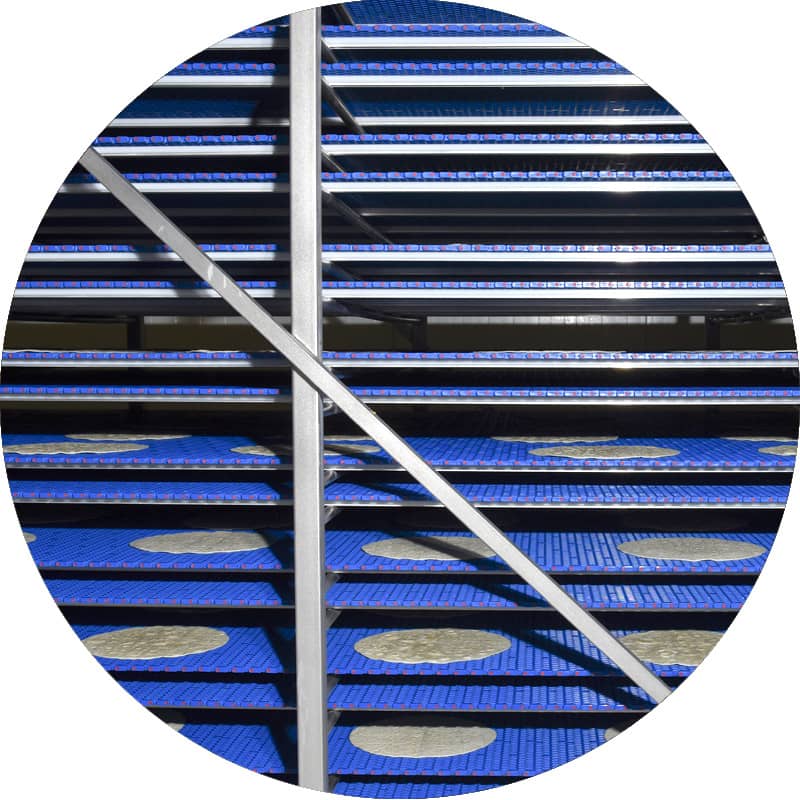

Packing

Delicate packaging process takes place on a specially inclined packaging machines. This is not an error in the set! We care about the final effect – so that you always get only a whole, not crushed product.

How we make our sauces and other sweet products? How fresh and juicy fruits turn into a delicious product enclosed in a convenient package?

You know these methods from traditional home cooking. But we in DIJO operate on a larger scale. All our shiny apparatus resembles indeed a set of pots, but the final product is the same – the highest class of sweetness. See for yourself!

The line for the production of sauces

Oh, it does not look like a grandmother’s cooking pot for jam. Do not you think?

More like a space station. This tangle of gleaming pipes and tubes around steel tanks gives delicious sauces for ice cream. We were afraid a little, if taste of these sauces will be too cosmic, but it turned out that the most modern equipment carries the taste of fruit and chocolate bottles without any prejudice.|

Our strawberry sauce from the new line tastes so good that the pot and grandmother lose competition. Anyway – give it a try!

The line for the production of poppies

Our confectionery decoration can be painstakingly made for a week in such an alley of ancient drums.

You can also use such a device with the appearance of a modern washing machine.

It does the same thing as drums, but without human intervention, and seven times faster.

We only colour our poppies in the old way – in old drums. Why? Because the eye and the hand of man are often better than the most perfect machine.